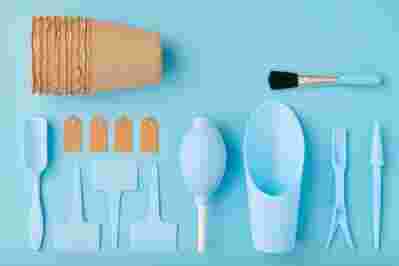

SourcifyChina is committed to providing professional, comprehensive plastic fabrication solutions for OEM/ODM clients.

We offer a range of plastic manufacturing services, including extrusion, injection molding, 5-axis machining, silkscreen, die cutting, and thermoforming, to create high-quality plastic components. Our expertise includes special surface treatments such as anti-fog, super abrasion resistance, and anti-glare on materials like polycarbonate and acrylic. Additionally, we provide integration with metal components and offer assembly services to deliver finished products to our customers.

Our advanced manufacturing methods, including laser cutting, 5 axis CNC machining, thermoforming, polishing, and injection molding, enable us to transform your design into a high-quality product.

SourcifyChina offers customized plastic products that are tailored to your specific design requirements. With our comprehensive plastic fabrication capabilities, we can advise you on how to incorporate the perfect features for your product’s final application. Our commitment to professionalism ensures that you’ll receive top-notch service every step of the way.

We offer UL94 V0 grade polycarbonate and acrylic mirrors ranging from 0.1mm to 12mm, made with advanced coating techniques to ensure scratch resistance.

Our polypropylene sheet exhibits exceptional chemical resistance and is highly resistant to contamination.

Our fog-free shower mirror features an enduring anti-fog coating, thereby enabling you to shave conveniently while in the shower. Additionally, we offer small-batch customization services.

Our team is adept at accommodating your tailored requirements, utilizing our expert laser cutting and polishing techniques.

With advanced coating techniques, we have UL94 V0 grade scratch resistant polycarbonate and acrylic mirror from 0.1mm to 12mm.

With advanced coating techniques, we have UL94 V0 grade scratch resistant polycarbonate and acrylic mirror from 0.1mm to 12mm.

Customizable and strong polycarbonate doors – choose your perfect design and features.

We offer a range of standard polycarbonate and acrylic pipes, as well as customized profiles tailored to your needs.

Our state-of-the-art manufacturing equipment spans 20,000 m2, ensuring the highest level of professionalism in producing your design.

Before the real production, our product manager can support you to optimize the design for real production and cost reduction. For example, if identify that you need a smooth edge instead of an optical grade for acrylic sheet, we can choose laser cutting or high polish CNC cutting. It can avoid the final polishing process, which can reduce the failure rate and cost significantly.

To create a see-through acrylic part, a variety of manufacturing methods are available, including laser cutting, CNC machining, injection molding, 3D printing, casting, among others. The method used depends on the desired quantity and optical quality.

We ensure top-notch fabrication quality by conducting incoming raw material inspections (IQC), in-process quality controls for each key process (IPQC), and outgoing quality controls (OQC). Our inspection activities strictly adhere to your drawings and testing requirements.

Have you heard of SourcifyChina? It is a sourcing company that specializes in connecting businesses with high-quality manufacturers in China. With years of experience in the industry, SourcifyChina offers a wide range of services including supplier identification, quality control, and logistics management. Contact them today to learn more!

We specialize in the production of plastic products, utilizing key technologies from raw plastic sheets to final assembled products. Our focus on quality and efficiency ensures professional results for every project.

We have obtained the ISO9001:2015 certification for our commitment to providing superior quality products. Our rigorous quality control measures include IQC (Incoming Quality Control), IPQC (In Process Quality Control), and OQC (Outgoing Quality Control). Consistency is key, and we ensure that our suppliers adhere to these same high standards.

According to different products, the general production lead time will be from 1 week to 4 weeks. If your product need a tooling for injection molding, it will take 4 to 6 weeks for tooling production. Thermoforming tooling will be easier which will take 2 to 3 weeks.

Some special products may need a longer lead time. Send us your drawings, our product manager will give you a real lead time and tell you why.

Our company prioritizes our customers above all else. We strive to accommodate your needs to the best of our abilities while maintaining our MOQ standards.

To ensure confidentiality, several of our clients choose to sign an NDA. Therefore, we are unable to provide any information on these products or their production methods on our website. If you would like to learn more, please send us an inquiry and our product manager will guide you through transforming your design into a tangible product.

Looking for affordable and high-quality non-glare acrylic signs? Look no further! Our prices are 80% less than our competitors, and we guarantee top-notch signage. Order now and see for yourself the value we offer.

CEO

Don’t miss out on our incredible offer of 80% off our high-quality non-glare acrylic signs! We’re grateful you’ve chosen us as your go-to source for all your signage needs.

ABC

Our highly skilled team takes great pride in meticulously creating acrylic signage that not only surpasses expectations but also fits within each client’s unique budget.

Buyer

Our team of experts is dedicated to providing you with a prompt and polished quote.